Clean Duct Package Cabinet Precision Commercial Industrial Central Air Conditioner

Variable refrigerant flow (VRF), also known as variable refrigerant volume (VRV), is an HVAC technology.

Because of the excellent technology, our Ceiling Concealed Fan Coil Unit, Wall Mounted Split Air Conditioner, Insulated Copper Tube are sold all over the world. Our company's team is young, united, progressive, and the average age is low, which is the age of youth. For many years, we have been adhering to the concept of 'producing high-quality products' and leading the development of the same industry. We focus on quality while emphasizing the importance of serving customers, always taking customer demand as the guide, whether it is conventional products or special customized products, we can do what customers want. We constantly develop new products and improve our service level according to the market demand and users' expectation, and give full play to the advantages of resources in all aspects, integrate scientific and technological research and development, manufacturing and sales network. We follow the core value concept of the group company and comprehensively sort out, revise and improve the rules and regulations, especially the post responsibility system, performance assessment and other systems.

Variable refrigerant flow (VRF), also known as variable refrigerant volume (VRV), is an HVAC technology. Like ductless mini splits, VRFs use refrigerant as the cooling and heating medium. This refrigerant is conditioned by a single or multiple condensing units (which may be outdoors or indoors, water or air cooled), and is circulated within the building to multiple indoor units.VRF systems, unlike conventional chiller-based systems, allow for varying degrees of cooling in only certain areas, reducing energy consumption.

VRF system outdoor units have all inverter driven compressors. This means their speed can be varied simply by changing the frequency of power supply to that compressor. As the speed changes, so does the amount of refrigerant delivered, allowing the compressor to operate continuously rather than repeatedly cycle on and off. There are two types of VRF systems: heat recovery and heat pump. The biggest difference is that heat recovery units can heat and cool at the same time, while heat pump units can only heat or cool at once. So, heat recovery systems, which improve efficiency by taking heat from one space and redistributing it to another, are ideal for anywhere you need zone-by-zone control—like a hotel or assisted living facility. And heat pump systems are great for spaces where only one mode of operation is needed, like a bank.As the speed changes, so does the amount of refrigerant delivered, allowing the compressor to operate continuously rather than repeatedly cycle on and off.

AMV X Multi inverter vrf system

All DC Inverter Technology;All DC Inverter Compressor;Technology of Maximum Torque Control with Minimum Current; 180° Sine Wave DC Speed Varying Technology; Sensorless DC Inverter Fan Motor; Non-polar CAN technology;88HP Max Capacity;

Features:

1.All DC inverter technology to improve compression efficiency

All DC inverter compressor and high-performance high pressure chamber are adopted to reduce loss of overheat and improve compression efficiency from direct intake. Compared with low pressure chamber, the compression efficiency is improved. High-efficient permasyn motor is adopted to provide better performance than traditional DC inverter compressor.

2. Sensorless DC inverter fan motor

Stepless speed regulation ranges from 5Hz to 65Hz.Compared with traditional inverter motors, the operation is more energy-saving.

3.Technology of maximum torque control with minimum current

It can reduce energy loss caused by device winding so as to realize higher efficiency.

4.Low-frequency torque control

It can directly control motor torque, through which fan motor can run at a low speed. Users will feel more comfortable while requirements of the system are also met.

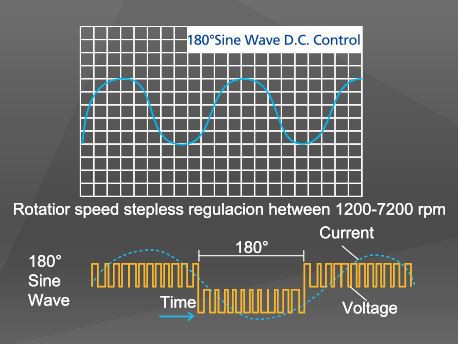

5.180° sine wave DC speed varying technology

It can satisfy various places’ demands for different temperature and is able to save a great deal of electricity and provide users with utmost comfort at the same time.

6.6 basic modules to meet different requirments.128HP max capacity-the largest free combination.

6 basic models.from 8HP to 32HP

Max capacity of single outdoor unit reaches 32HP and max combination capacity is even up to 128HP, in an industry leading level.

7.Non-polar CAN technology to improve communication efficiency

We adopt non-polar CAN communication technology in the industry. CAN communication technology provides quicker system response speed, more convenient installation debugging and more reliable communication data.

8.Wide range of voltage and operation condition

Working voltage range of AMV X system has been improved to 320V-460V, which surpasses the national standard of 342V-420V. For places with unsteady voltage, this system can still be running well.

9.Wider applicable location

AMV X can realize a combination of 4 outdoor unit modules connecting with as many as 80 indoor units. It’s especially applicable for business building or hotels.

10.Refrigerant storage and distribution

The AMV X system is designed without liquid receiver and the excess refrigerant is stored in the piping, which can minimize the refrigerant charging volume and enhance the control accuracy of refrigerant.

11. Long pipe & height difference

1.The total pipe length: 1000 m.

2.The longest pipe length: 200 /240m.

3.Height deference:Outdoor unit. Above<90m<90m.4.Outdoor unit below<110m.

5.Height difference between indoor units: 30m.

6.Length from first indoor distributor to last indoor unit 90 m.

7.Communication wire length can be upto 1000m.

12. Wide outdoor operation range(380v)

Max.cooling operating temperature is up to 55°C.

Low ambient temperature of cooling mode can be downto-10℃.

13.World famous brand DC Inverter compressor

High efficiency Oilseparate structure,High efficiency DC Fan Motor,Middle partition Improve the efficiency;Reduce quality.Highefficiency Gas-liquid separater,Low noise design of cylinder to reduce noise when exhaust high pressure gas,Low deformationcylinder design to improve the lifetime,High efficiency Movement oil supply mechanismto Ensure oil supplyand reduce noise.

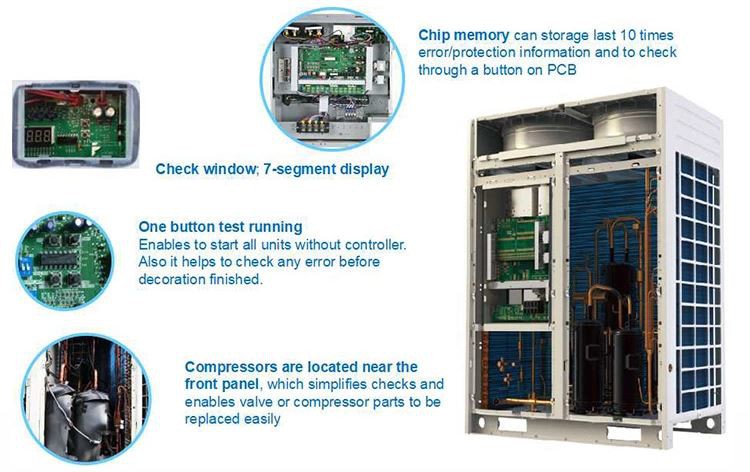

14. Service window on front cover

Thanks to the service window, checking outdoor unit's status and setting is now easy, no need to remove the front cover

15.Certificates.

16.More than 11 different indoor unit can be connected with outdoor unit.

Our organization has a top quality assurance procedure have already been established for Clean Duct Package Cabinet Precision Commercial Industrial Central Air Conditioner. We aim at 100% product qualification rate, 100% contract fulfillment rate, and 100% service satisfaction rate. Adhering to the concept of 'User's success is our achievement', we sincerely welcome friends from all walks of life to come and guide us, and we are willing to sincerely cooperate with you to create bright future. With strict production technology, perfect testing methods, and complete production facilities, we have a place in the fierce market competition and meet the continuous needs of customers.

Hot Tags: vrf dc inverter air conditioner, China vrf dc inverter air conditioner manufacturers, suppliers, factory, One Way Cassette Fan Coil Unit, Round Way Cassette Indoor Unit, Air Conditioning Straight Tube, Pancake Coil, Dehumidifier, Round Ceiling Diffuser